AL-KO ECO-SYS drying system – with maximum energy efficiency

To ensure economical use of biogas systems, a high degree of drying of the biomass used is necessary. The AL-KO ECO-SYS drying system dries biological materials such as wood chips and bulk material in an energy-efficient manner, thus improving the cost-effectiveness of the entire system.

Receive consultation in person

Description

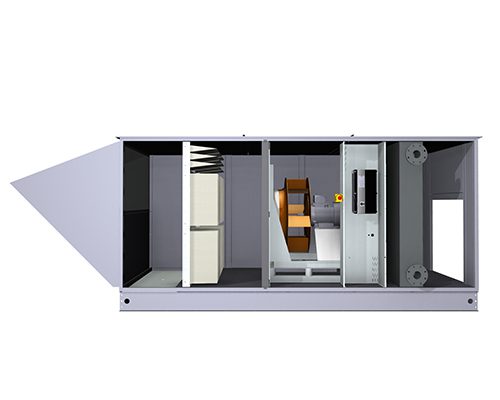

AL-KO ECO-SYS drying systems are suitable for drying all biological materials such as wood chips, logs or grain. Depending on the selection of the corresponding unit size, up to twelve containers can be supplied with warm air at the same time and organic bulk materials and other agricultural products can be dried. AL-KO offers the ECO-SYS drying systems in six sizes – for air volumes between 12,000 and 65,000 m3/h. AL-KO also offers the LT 440 aeration spear dryer for drying grain, which can be flexibly used on a conventional trailer.

Benefits

- High quality, weatherproof

- Low energy consumption

- Generous, low resistance design

- Slow running fan

- Standard product with TÜV-approved performance and valid performance and sound certificates

- Acoustically and thermally insulated, double-walled housing

- Demand-dependent power control by frequency converter

- Max. 0.9 KWh/kg energy requirement for wood chip drying (according to the German Renewable Energy Act (Erneuerbare-Energien-Gesetz, EEG))

- Contribution to achieving the CHP bonus according to EEG

Installation

- Ex works plug & play ready

- Installation and commissioning of the system can be carried out on site by any heating/ventilation contractor

Maintenance and operation

- Maintenance-free thanks to upstream pocket air filter

- Long filter life

- Contamination indicator

Quality components and functional units

We offer our own products as well as components and functional units from various manufacturers. All components and functional units are tested by AL-KO Air Technology.

Technical data

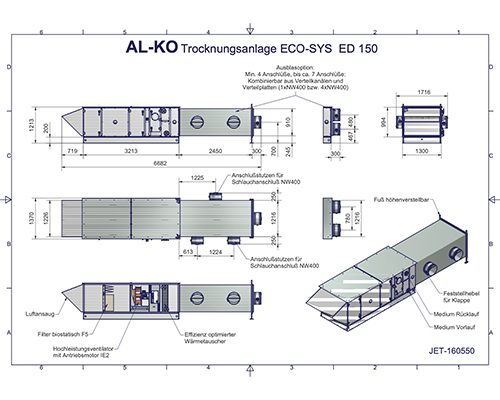

AL-KO ECO-SYS drying system

| Size | ED 150 | ED 250 | ED 370 | ED 650 | ED 800 | ED1200 |

|---|---|---|---|---|---|---|

| Heat output in kW | 150 | 250 | 370 | 650 | 800 | 1200 |

| Air volume in m³/h | 12,000 | 19,000 | 26,000 | 45,000 | 52,000 | Upon request |

| Motor power in kW | 4.0 / 7.5 | 5.5 / 11 | 7.5 / 15 | 15 / 30 | 30 | Upon request |

Drying capacity

| Size | ED 150 | ED 250 | ED 370 | ED 650 | ED 800 | ED1200 |

|---|---|---|---|---|---|---|

| Recommended connection nozzles for mobile containers | 4-7 or combinations* | 7-10 or combinations* | 8-12 or combinations* | 14-22 or combinations* | 16-24 or combinations* | Combination or drying box* |

| When using stationary drying boxes | individual design | individual design | individual design | individual design | individual design | individual design |

* Recommendation: 2 D nozzles = 400 mm per container